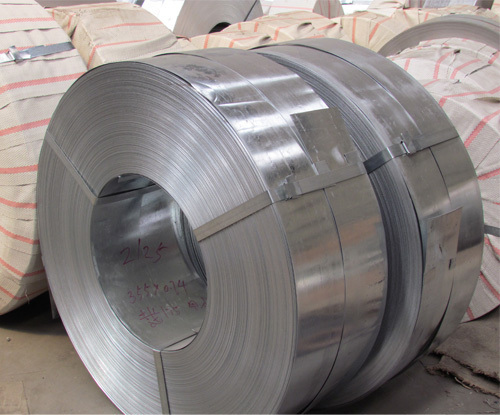

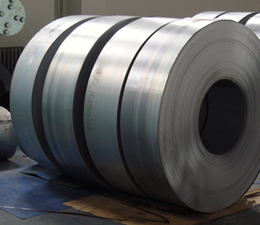

235 strip steel

Short Description:

The strip steel is generally supplied in coils, which has the advantages of high dimensional accuracy, good surface quality, easy processing, material saving and so on. The same as the steel plate, the strip steel is divided into ordinary strip steel and high-quality strip steel according to the material used; According to the processing method, it is divided into hot-rolled strip and cold-rolled strip.

The production process of cold rolled strip is generally as follows: pickling → rolling → process lubrication → annealing → leveling → shearing → packaging.

Cold rolled strip process: Pickling – rolling – annealing – synchronous lubrication of rolling size – antirust oil – leveling and sizing – polishing – packaging

Hot strip rolling process: heating furnace — dephosphorization machine — roughing mill — dephosphorization machine — finishing mill — surface quality inspection instrument — layer cooling — coiler — baler — marking machine — rolling stock slab

Hot rolled strip production process: firstly, raise the temperature in the heating furnace to the required rolling temperature, then enter the roughing dephosphorization machine through the roller table to treat the iron oxide scale generated by the slab, then enter the roughing rolling unit to roll the width and thickness of the strip, and then transport it from the roller table to the finishing dephosphorization machine to treat the iron oxide scale generated on the surface of the strip, Enter the finishing rolling unit for more precise rolling of the thickness and width of the strip steel. After the surface temperature of the strip steel is strictly controlled by the roller table through layer cooling before coiling, it enters the coiler to become a steel coil. Finally, it is bundled, sprayed and sent to the coil warehouse for storage and packaging.