Best Price on Poly Tube Fittings - Hydraulic cylinder seamless steel pipe – Wenyue

Short Description:

Best Price on Poly Tube Fittings - Hydraulic cylinder seamless steel pipe – Wenyue Detail:

Hydraulic cylinder seamless steel pipe is suitable for oil, hydraulic cylinder, mechanical processing, thick wall pipeline, chemical industry, electric power, boiler industry, high temperature, low temperature and corrosion resistance seamless steel pipe, and it is suitable for petroleum, aviation, smelting, food, water conservancy, electric power, chemical industry, chemical fiber, medical machinery and other industries.

Due to the surface residual compressive stress left in the surface layer of hydraulic cylinder, it is helpful to close the surface micro cracks and hinder the expansion of erosion. Thus, the corrosion resistance of the surface can be improved, and the generation or expansion of fatigue crack can be delayed, thus the fatigue strength of quilted tube can be improved. Through rolling forming, a layer of cold work hardening layer is formed on the rolling surface, which reduces the elasticity of contact surface of grinding pair.

Therefore, the wear resistance of the inner wall of the quilting tube is improved and the burn caused by grinding is avoided. After rolling, the reduction of surface roughness can improve the matching properties.

Rolling is a kind of chip free machining, which uses the plastic deformation of metal at room temperature to flatten the micro unevenness of the workpiece surface, so as to change the surface structure, mechanical properties, shape and size. Therefore, this method can achieve both finishing and strengthening at the same time, which is impossible for grinding.

No matter what kind of processing method is used, there will always be fine uneven tool marks on the surface of the parts, resulting in staggered peaks and valleys, Rolling processing principle: it is a kind of pressure finishing, which uses the cold plastic characteristics of metal at room temperature, and applies certain pressure to the surface of the workpiece by rolling tools to make the metal on the surface of the workpiece produce plastic flow and fill in the original residual low concave trough, so as to reduce the surface roughness of the workpiece. Due to the plastic deformation of the rolled surface metal, the surface structure is cold hardened and the grains become fine, forming a dense fibrous layer and forming a residual stress layer. The hardness and strength of the surface are improved, so the wear resistance, corrosion resistance and compatibility of the workpiece surface are improved. Rolling is a cutting free plastic processing method.

Advantages of seamless steel pipe for hydraulic cylinder:

1. The surface roughness can reach RA ≤ 0.08 & micro; M.

2. The ovality can be ≤ 0.01mm.

3. The surface hardness is increased to eliminate the stress deformation, and the hardness is increased HV ≥ 4 °

4. After machining, there is residual stress layer, and the fatigue strength is increased by 30%.

5. It can improve the matching quality, reduce wear and prolong the service life of parts, but the processing cost of parts is reduced.

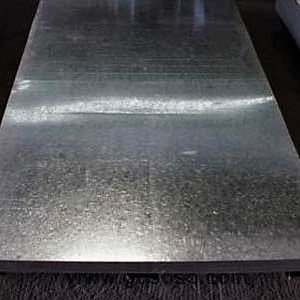

Product detail pictures:

Related Product Guide:

With a complete scientific quality management system, good quality and good faith, we win good reputation and occupied this field for Best Price on Poly Tube Fittings - Hydraulic cylinder seamless steel pipe – Wenyue, The product will supply to all over the world, such as: Cannes, Ghana, Venezuela, We will initiate the second phase of our development strategy. Our company regards "reasonable prices, efficient production time and good after-sales service" as our tenet. If you are interested in any of our products or would like to discuss a custom order, please feel free to contact us. We are looking forward to forming successful business relationships with new clients around the world in the near future.

The manufacturer gave us a big discount under the premise of ensuring the quality of products, thank you very much, we will select this company again.