-

Low MOQ for China ANSI B16.5/En1092/ DIN Forged Carbon Steel Stainless Steel RF FF Welding Neck /Threaded/Blind/Slip on/Lap Joint/Socket Welding Flange

WN Flange, So Flange, LJ Flange, LWN Flange, SW Flange, Orifice Flange, Reducing Flange, figure 8 blind (blank&Spacer) Special Flange: According to the drawing Picture

-

Supply OEM China 304 304L 316 Ss Stainless Steel Seamless Pipe Factory

Galvanized seamless steel pipe is hot-dip galvanized, so the amount of zinc plating is very high, the average thickness of zinc coating is more than 65 microns, and its corrosion resistance is much different than that of hot-dip galvanized pipe. The regular galvanized pipe manufacturer can use cold galvanized pipe as water and gas pipe. The zinc coating of cold galvanized steel pipe is electroplated layer, and the zinc layer is separated from the steel pipe substrate. The zinc layer is thin and easy to fall off because it is attached to the steel pipe substrate. Therefore, its corrosion resistance is poor. It is forbidden to use cold galvanized steel pipe as water supply steel pipe in new residential buildings.

-

Chinese Professional China High Quality 5 in 1 IPL Shr Opt ND YAG Laser RF IPL Hair Removal Skin Rejuvenation Skin Care Multifuctional Beauty Equipment

The inner and outer plastic-coated steel pipes are made by melting a layer of polyethylene (PE) resin, ethylene-acrylic acid copolymer (EAA), epoxy (EP) powder, and non-toxic polycarbonate with a thickness of 0.5 to 1.0mm on the inner wall of the steel pipe. The steel-plastic composite pipe composed of organic substances such as propylene (PP) or non-toxic polyvinyl chloride (PVC) not only has the advantages of high strength, easy connection, and resistance to water flow, but also overcomes the corrosion of steel pipes when exposed to water. Pollution, scaling, low strength of plastic pipes, poor fire-fighting performance and other shortcomings, the design life can be up to 50 years. The main disadvantage is that it must not be bent during installation. During thermal processing and electric welding cutting, the cutting surface should be painted with the non-toxic normal temperature curing glue provided by the manufacturer to repair the damaged part.

-

Well-designed China High Quality Fruit Apple Beef Blueberry Bamboo Coconut Cashew Chili Pepper Dates Dog Feed Fish Fig Ginger Garlic Banana Agriculture Food Drying Machine

The strength, versatility, and affordability of steel bar make it one of the most widely used manufacturing/construction materials in the world. Industrial Metal Supply offers both hot rolled steel bar and cold rolled steel bar, in a variety of profiles and diameters; cut-to-length service is available to give you the perfect steel bar for your specific application.

-

OEM/ODM Factory China Factory Wholesaler Good Price Nice Quality Perfumed Laundry Detergent Powder

Steel Plate is one of the most popular hot rolled, low carbon steel plates used in manufacturing, fabrication, and repair projects. A36 Steel plate adds strength and rigidity to any project at a lower price compared to other grades of steel plate. It is easy to weld, cut, form and machine. Metals Depot stocks hundreds of thicknesses and sizes of steel plate that you can buy online in ready to ship precut or mill sizes or you can order just what you need custom Cut to Size in small or large quantity at wholesale prices.

-

factory low price China High Quality Good Price 40mm Wall Kitchen Mixer

Used in home appliances construction, machinery manufacturing, container manufacturing, shipbuilding, bridges, etc.

-

Supply OEM China Factory Wholesaler Good Price Nice Quality Perfumed Laundry Detergent Powder

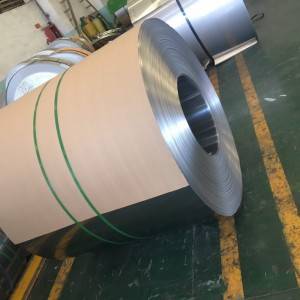

Innovation, excellent and reliability are the core values of our company. These principles today much more than ever form the basis of our success as an internationally active mid-size business for Online Exporter China 304 316 En/DIN 1.4401 Hot Rolled Stainless Steel Coil Duplex 904L 2205 2507, Honesty is our principle, professional operation is our work, service is our goal, and customers’ satisfaction is our future!

-

Factory Price China High Quality Metal Scrap Cutting Machine Steel Sheet Shearing Machine Guillotine Shear

Seamless Steel Pipe,as the name suggests,is a pipe without a seam or a weld-joint.Seamless Steel Pipes is a tubular section or hollow cylinder,usually but not necessarily of circular cross-section,used mainly to convey substances which can flow-liquids and gases(fluids),slurries,powders,powders and masses of small solids. The production of our seamless steel pipes is tightly regulated and all of the pipes we produced have been fully tested to international standards to ensure we only supply the hightest products.

-

Well-designed China 2021 Hot Sale Good Price High Quality Steel Wire Rope Galvanized/Ungalvanized Wire Rope Iron Cable Steel Cable

WN Flange, So Flange, LJ Flange, LWN Flange, SW Flange, Orifice Flange, Reducing Flange, figure 8 blind (blank&Spacer) Special Flange: According to the drawing Picture

-

Newly Arrival China Full Sizes of Septic Tank with Good Price for Water Treatment /High Quality Bio Tank with Wholesale Price

Galvanized seamless steel pipe is hot-dip galvanized, so the amount of zinc plating is very high, the average thickness of zinc coating is more than 65 microns, and its corrosion resistance is much different than that of hot-dip galvanized pipe. The regular galvanized pipe manufacturer can use cold galvanized pipe as water and gas pipe. The zinc coating of cold galvanized steel pipe is electroplated layer, and the zinc layer is separated from the steel pipe substrate. The zinc layer is thin and easy to fall off because it is attached to the steel pipe substrate. Therefore, its corrosion resistance is poor. It is forbidden to use cold galvanized steel pipe as water supply steel pipe in new residential buildings.

-

100% Original China Supplier Crusher Manufacturers 200 Tph Construction Waste Complete Crushing Line Good Price Quarry Rock Stone Crushing Plant Machines for Sale

The inner and outer plastic-coated steel pipes are made by melting a layer of polyethylene (PE) resin, ethylene-acrylic acid copolymer (EAA), epoxy (EP) powder, and non-toxic polycarbonate with a thickness of 0.5 to 1.0mm on the inner wall of the steel pipe. The steel-plastic composite pipe composed of organic substances such as propylene (PP) or non-toxic polyvinyl chloride (PVC) not only has the advantages of high strength, easy connection, and resistance to water flow, but also overcomes the corrosion of steel pipes when exposed to water. Pollution, scaling, low strength of plastic pipes, poor fire-fighting performance and other shortcomings, the design life can be up to 50 years. The main disadvantage is that it must not be bent during installation. During thermal processing and electric welding cutting, the cutting surface should be painted with the non-toxic normal temperature curing glue provided by the manufacturer to repair the damaged part.

-

Wholesale Discount China Disposable Medical High Quality PVC Soft Hose I. V Infusion Set ISO13485 CE

The strength, versatility, and affordability of steel bar make it one of the most widely used manufacturing/construction materials in the world. Industrial Metal Supply offers both hot rolled steel bar and cold rolled steel bar, in a variety of profiles and diameters; cut-to-length service is available to give you the perfect steel bar for your specific application.