-

Electro galvanized alloy strip steel

The strip steel is generally supplied in coils, which has the advantages of high dimensional accuracy, good surface quality, easy processing, material saving and so on. The same as the steel plate, the strip steel is divided into ordinary strip steel and high-quality strip steel according to the material used; According to the processing method, it is divided into hot-rolled strip and cold-rolled strip.

-

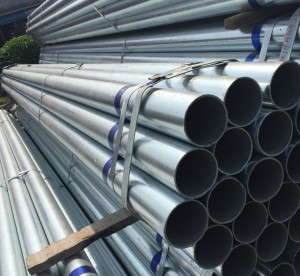

I-beam processing

I-beam, also known as universal beam, is a long strip of steel with I-shaped section. I-beam is divided into hot-rolled I-beam and light I-beam. It is a section steel with I-section shape.

-

Galvanized I-beam

I-beam, also known as universal beam, is a long strip of steel with I-shaped section. I-beam is divided into hot-rolled I-beam and light I-beam. It is a section steel with I-section shape.

-

Custom I-beam

I-beam, also known as universal beam, is a long strip of steel with I-shaped section. I-beam is divided into hot-rolled I-beam and light I-beam. It is a section steel with I-section shape.

-

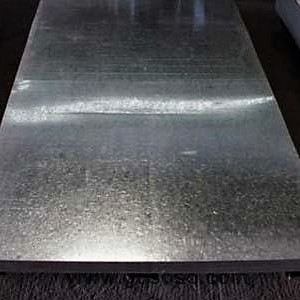

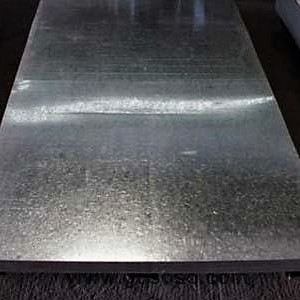

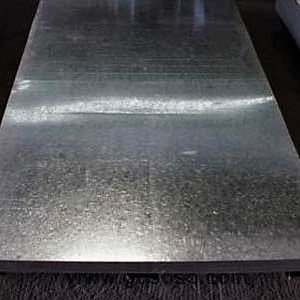

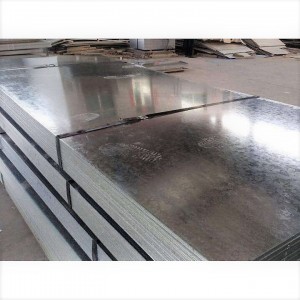

Non standard galvanized sheet

Galvanized sheet refers to the steel plate with a layer of zinc on the surface. Galvanizing is an economic and effective rust prevention method often used. About half of the world’s zinc production is used in this process.

-

Alloy galvanized sheet

Galvanized sheet refers to the steel plate with a layer of zinc on the surface. Galvanizing is an economic and effective rust prevention method often used. About half of the world’s zinc production is used in this process.

-

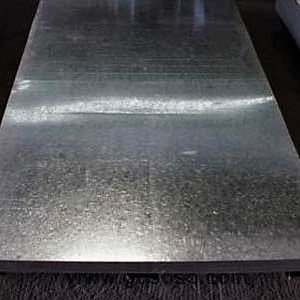

hot dip galvanized

Galvanized steel plate is a welded steel plate with hot-dip or electro galvanized coating on the surface. It is generally widely used in construction, household appliances, vehicles and ships, container manufacturing, electromechanical industry and so on.

-

Electro galvanized split plate

Galvanized sheet refers to the steel plate with a layer of zinc on the surface. Galvanizing is an economic and effective rust prevention method often used. About half of the world’s zinc production is used in this process.

-

235 galvanized sheet

Galvanized sheet refers to the steel plate with a layer of zinc on the surface. Galvanizing is an economic and effective rust prevention method often used. About half of the world’s zinc production is used in this process.

-

195 galvanized sheet

Galvanized steel plate is coated with a layer of metal zinc on the surface of the steel plate to prevent corrosion on the surface of the steel plate and prolong its service life. This kind of galvanized steel plate is called galvanized steel plate.

-

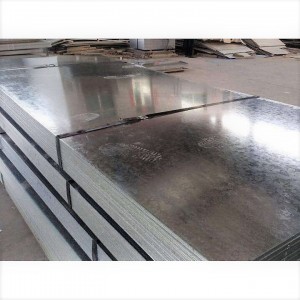

Electro galvanizing

Electro galvanizing: also known as cold galvanizing in the industry, it is the process of forming a uniform, dense and well bonded metal or alloy deposition layer on the surface of the workpiece by electrolysis.

Compared with other metals, zinc is relatively cheap and easy to be plated. It is a low value anti-corrosion electroplated coating. It is widely used to protect iron and steel parts, especially to prevent atmospheric corrosion, and for decoration. Plating technology includes bath plating (or hanging plating), barrel plating (suitable for small parts), blue plating, automatic plating and continuous plating (suitable for wire and strip).

-

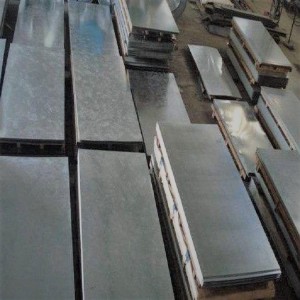

Galvanized split plate

The open plate is a steel plate with a certain thickness and width rolled according to the user’s requirements. The original flat plate is rolled into the size required by the national standard when the steel factory leaves the factory. Generally, the original flat plate has strict size, good performance and high price. The flat panel is relatively cheap, and the size is slightly different