OEM Factory for China Good Prices 900W Fogging Portable Making Pulse for Fumigation Smoke Sprayer Fog Machine

Short Description:

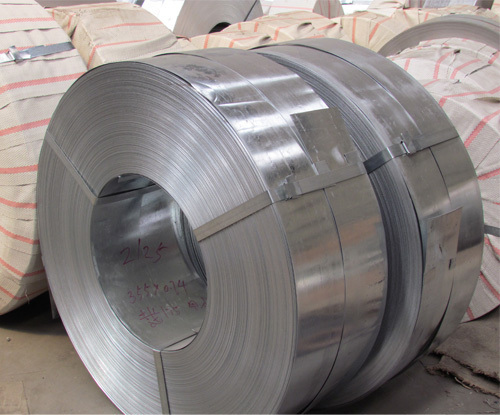

The strip steel is generally supplied in coils, which has the advantages of high dimensional accuracy, good surface quality, easy processing, material saving and so on. The same as the steel plate, the strip steel is divided into ordinary strip steel and high-quality strip steel according to the material used; According to the processing method, it is divided into hot-rolled strip and cold-rolled strip.

Our focus on should be to consolidate and enhance the quality and repair of present products, in the meantime constantly establish new products to meet unique customers’ requires for OEM Factory for China Good Prices 900W Fogging Portable Making Pulse for Fumigation Smoke Sprayer Fog Machine, We welcome you to join us within this route of creating a affluent and productive company with each other.

Our focus on should be to consolidate and enhance the quality and repair of present products, in the meantime constantly establish new products to meet unique customers’ requires for China Fogging Machine, Machine, Our Company policy is “quality first, to be better and stronger, sustainable development” . Our pursuit goals is “for society, customers, employees, partners and enterprises to seek reasonable benefit”. We aspirate to do cooperate with all different the auto parts manufacturers, repair shop, auto peer , then create a beautiful future! Thank you for taking time to browse our website and we would welcome any suggestions you may have that can help us to improve our site.

The production process of cold rolled strip is generally as follows: pickling → rolling → process lubrication → annealing → leveling → shearing → packaging.

Cold rolled strip process: Pickling – rolling – annealing – synchronous lubrication of rolling size – antirust oil – leveling and sizing – polishing – packaging

Hot strip rolling process: heating furnace — dephosphorization machine — roughing mill — dephosphorization machine — finishing mill — surface quality inspection instrument — layer cooling — coiler — baler — marking machine — rolling stock slab

Hot rolled strip production process: firstly, raise the temperature in the heating furnace to the required rolling temperature, then enter the roughing dephosphorization machine through the roller table to treat the iron oxide scale generated by the slab, then enter the roughing rolling unit to roll the width and thickness of the strip, and then transport it from the roller table to the finishing dephosphorization machine to treat the iron oxide scale generated on the surface of the strip, Enter the finishing rolling unit for more precise rolling of the thickness and width of the strip steel. After the surface temperature of the strip steel is strictly controlled by the roller table through layer cooling before coiling, it enters the coiler to become a steel coil. Finally, it is bundled, sprayed and sent to the coil warehouse for storage and packaging.

Our focus on should be to consolidate and enhance the quality and repair of present products, in the meantime constantly establish new products to meet unique customers’ requires for OEM Factory for China Good Prices 900W Fogging Portable Making Pulse for Fumigation Smoke Sprayer Fog Machine, We welcome you to join us within this route of creating a affluent and productive company with each other.

OEM Factory for China Fogging Machine, Machine, Our Company policy is “quality first, to be better and stronger, sustainable development” . Our pursuit goals is “for society, customers, employees, partners and enterprises to seek reasonable benefit”. We aspirate to do cooperate with all different the auto parts manufacturers, repair shop, auto peer , then create a beautiful future! Thank you for taking time to browse our website and we would welcome any suggestions you may have that can help us to improve our site.