Plastic coated steel pipe

Short Description:

The inner and outer plastic-coated steel pipes are made by melting a layer of polyethylene (PE) resin, ethylene-acrylic acid copolymer (EAA), epoxy (EP) powder, and non-toxic polycarbonate with a thickness of 0.5 to 1.0mm on the inner wall of the steel pipe. The steel-plastic composite pipe composed of organic substances such as propylene (PP) or non-toxic polyvinyl chloride (PVC) not only has the advantages of high strength, easy connection, and resistance to water flow, but also overcomes the corrosion of steel pipes when exposed to water. Pollution, scaling, low strength of plastic pipes, poor fire-fighting performance and other shortcomings, the design life can be up to 50 years. The main disadvantage is that it must not be bent during installation. During thermal processing and electric welding cutting, the cutting surface should be painted with the non-toxic normal temperature curing glue provided by the manufacturer to repair the damaged part.

The inner and outer plastic-coated steel pipes are made by melting a layer of polyethylene (PE) resin, ethylene-acrylic acid copolymer (EAA), epoxy (EP) powder, and non-toxic polycarbonate with a thickness of 0.5 to 1.0mm on the inner wall of the steel pipe. The steel-plastic composite pipe composed of organic substances such as propylene (PP) or non-toxic polyvinyl chloride (PVC) not only has the advantages of high strength, easy connection, and resistance to water flow, but also overcomes the corrosion of steel pipes when exposed to water. Pollution, scaling, low strength of plastic pipes, poor fire-fighting performance and other shortcomings, the design life can be up to 50 years. The main disadvantage is that it must not be bent during installation. During thermal processing and electric welding cutting, the cutting surface should be painted with the non-toxic normal temperature curing glue provided by the manufacturer to repair the damaged part.

Plastic coated steel pipe product advantages:

1. Adapt to buried and humid environments, and can withstand high and very low temperatures.

2. Strong anti-interference ability, if the plastic-coated steel pipe is used as a cable bushing, it can effectively shield external signal interference.

3. Good pressure strength, the maximum pressure can reach 6Mpa.

4. Good insulation performance, as a protection tube for wires, leakage will never occur.

5. No burr, smooth pipe wall, suitable for wearing wires or cables during construction.

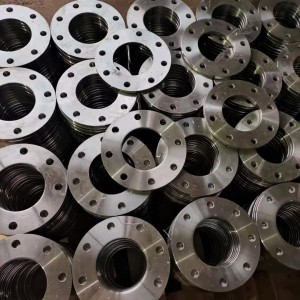

The specifications, types, and connection methods of plastic-coated steel pipes for cables have been diversified. Among them, small specifications can be produced up to 15mm, and there are no restrictions on large ones. Its types are galvanized outside, plastic coated inside and outside, etc., and it is a versatile type that can be used in any other fields. The connection method adopts welding, groove, flange and buckle wire connection, and the welding can adopt bimetal or non-destructive welding.